Fall is harvest time for most crops (we harvest our honey in early July), and that means harvest festivals. Mary and I set up our honey display/sale at the local agricultural museum’s harvest festival. The harvest festival we attend includes demonstrations of old farm equipment, with the star of the show star being a 1920s peanut threshing machine. In an era when honey extractors come with “Do not open while rotating” stickers, this pre-OSHA peanut thresher shows how far worker safety provisions have come over the years.

Early November for us is National Peanut Festival time (which is also our local Fair). To us beekeepers, we have two items of special interest; a honey competition and a club booth competition. The various honey competition classes are similar to the one you get at the Montgomery County Fair. Participation this year was excellent, and I’ve included a picture of the resulting product display.

This year, three of the four entries I made won ribbons’ I got first in extracting frame and in baked bread, and a second in beeswax. My extracted honey did not place, but that’s OK as I didn’t think it was all that good this year. Most of the honey we get in south Alabama will crystalize while you watch, and this year’s honey was no exception. For Fair entries, getting rid of the crystals forces one to choose between overheating the honey or entering honey that is not quite transparent. I chose to enter slightly cloudy honey.

More pleasing to me was seeing the quality and quantity of the entries improve every year.

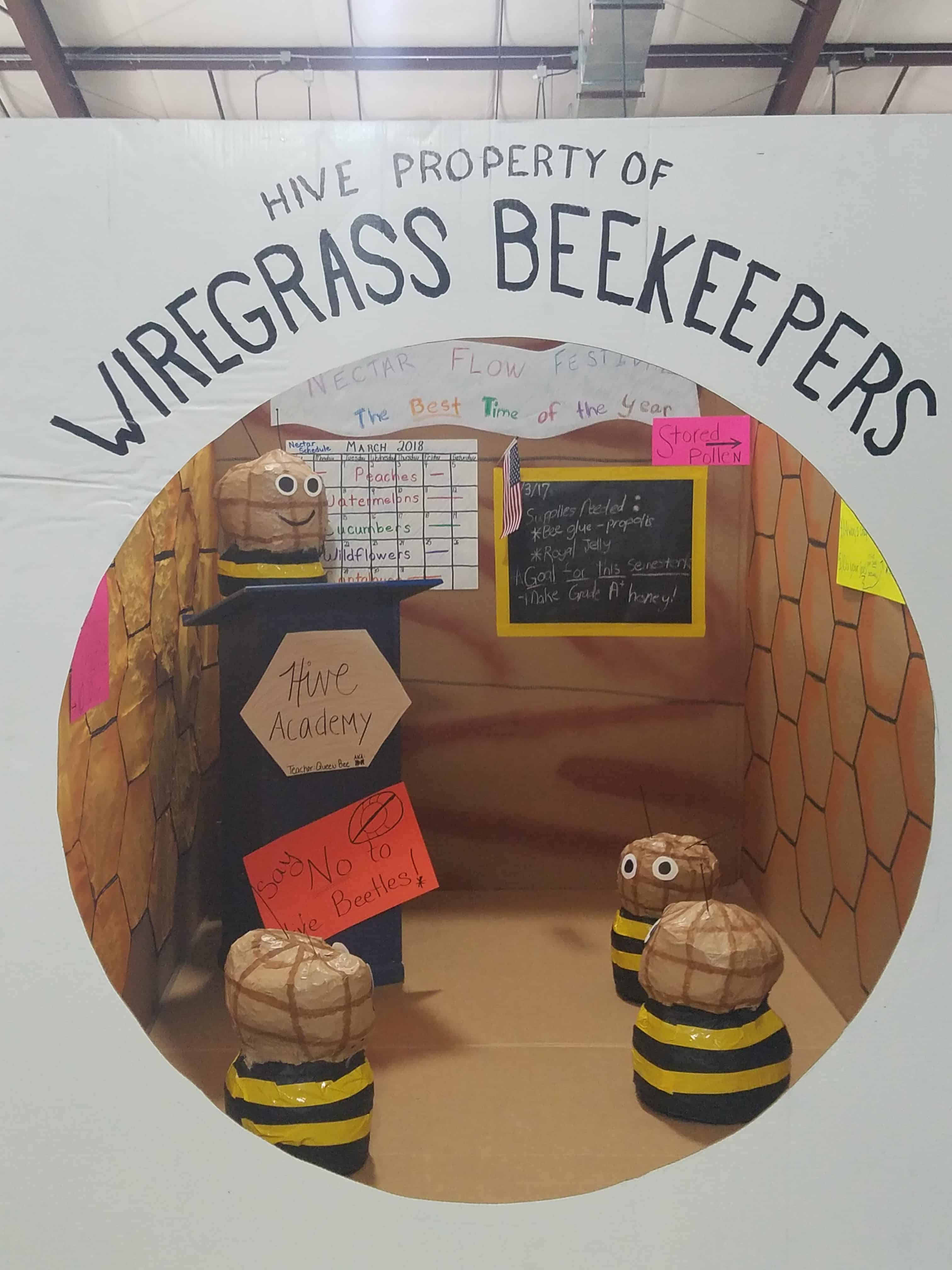

The club booth class at the Peanut Festival is different from anything I have seen at a Maryland fair. The basic idea is that each of the local agricultural clubs (e.g.; a high school’s Future Farmers of America club) are given a space to decorate based on the year’s Peanut Festival theme, which this year was “The Best Time of the Year”. As beekeepers, our best time of the year is the spring nectar flow, so our Wiregrass Beekeepers club booth depicted a whimsical scene inside a hive with the worker bees being instructed by the queen in how to collect nectar. While this isn’t a realistic description of what goes on in a hive, the result was quite nice and got the club a 7th place out of about 30 booths. I’ve included a picture of the booth.

I did take a look in my hives this week. I’ve always taught that one big colony going into winter is better than two little ones, so I combined two of my weak colonies. While it hurts a bit to lower my colony count, I can take solace in the expectation that I can fill the slot next March with a freshly caught swarm.

Two of my colonies needed feeding, which is 2/1 sugar syrup this time of year. Many years ago, I discovered a simple method for making 2/1 sugar syrup:

- Fill the teakettle and bring it to boil.

- Fill your mixing pot (I use my feeding pails) with dry granulated sugar.

- Put the mixing pot in the sink to keep any spills under control.

- Pour boiling water into the mixing pot to the level of the sugar.

- Stir to dissolve the sugar. The water level will go down as the sugar dissolves.

- Add more boiling water to maintain the level and keep stirring.

- The sugar will be dissolved when you can no longer feel grittiness with your stirring spoon.

- For me, I now put on the feeder pail lids and take the syrup pails out to the apiary.

South Alabama bees fly all year round, but the next significant nectar flow won’t start until the end of January. I’ll probably have to feed these two colonies several times over the course of the winter. I’ll also be checking in on my other colonies during the winter to see if they need feed too. Also during the winter will come Varroa checks and my first use of formic acid as a mite treatment.

And that’s the November news from the South.

-Bill Miller